About Us

Inra Optics is a company, renowned for manufacturing and supplying excellent quality Optical Components & lens assemblies. The company is in this field since 1998 and has extended its network to clients across the domestic market. The company is based in Ambala Cantt., Haryana and has its supply chain expanded all over the country. Mr. Ravi Bhardwaj, the Proprietor of the company is making every possible effort to lead the company on the path of success.

WHY PEOPLE TRUST US

Quality Assurance

For testing the quality of optical components manufactured by us,we take services of I.D.D.C. (a govt. organisation).

Our Infrastructure

Our manufacturing unit has all basic plant & machines required for lens making.Machines available with us are:-

Trepanning, Curve Generator, Grinding, Pitch Polishing and Centering & Edging.

Clients / Customers

For the satisfaction of the clients, we offer them Optical Components with all the desirable features. Along with reasonable price and easy payment mode, our ethical business practices help us in attaining the maximum client satisfaction while building long-lasting relationship with them.

22

year of experiencs

12

awad by GOV

1000

Happy Clients

06AFGPB0135C1ZE

GST No.

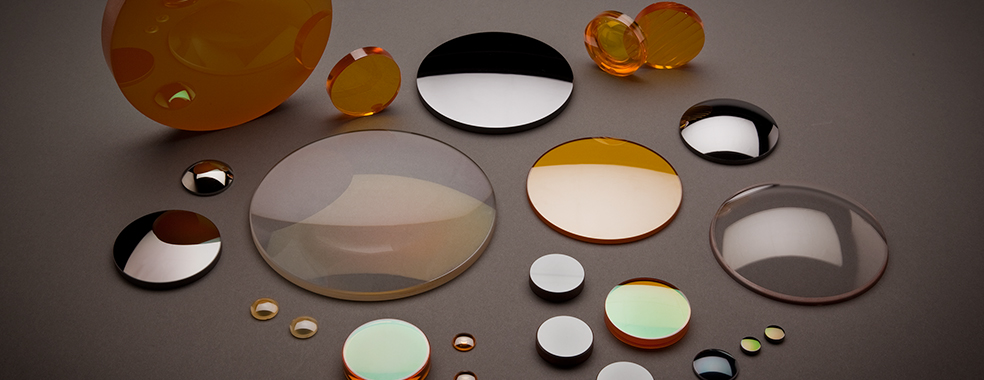

Products & Services Portfolio

- Singlets These include single lenses generally made by optical sheet glass or bk-7 glass. These are Plano convex, Bi-convex, Plano concave, Biconcave, or Meniscus lenses

- Rod lens & cylindrical lenses: These are used for linear or one dimensional shaping of a light source. Cylindrical lenses may have a Plano Concave or Plano Convex shape. Rod lenses are in the shape of a regular rod with cylindrical surface polished. Flat faces are also polished if required.

- IR lenses & Laser Optics we process germanium which is widely used now a days for thermal imaging. We also process ZnSe which also has wide application in lasers

- Custom Optics & Subassemblies We can make optical components to customers specifications, made to suit individual requirements

- Reverse Engineering Prototype development Over the time we have developed skills to reverse engineer an optical assembly or subassembly upto component level. Here we can De-cement a doublet achromat and can find out the glass material used without damaging the original component. Here we try to find out the actual glass material used. We can make a prototype for you if you have designs ready with you or we can also get it designed for you.